“The Constraints”. While electronic schematics provide a practical way to represent the components and connections within a circuit, they are ultimately a simplification that overlooks important aspects of how the circuit actually behaves. Connection lines are assumed to have no resistance, inductance, parasitic capacitance, or propagation delay, and Kirchhoff’s laws are applied as if they perfectly determine all voltages and currents.

High-Frequency Signals

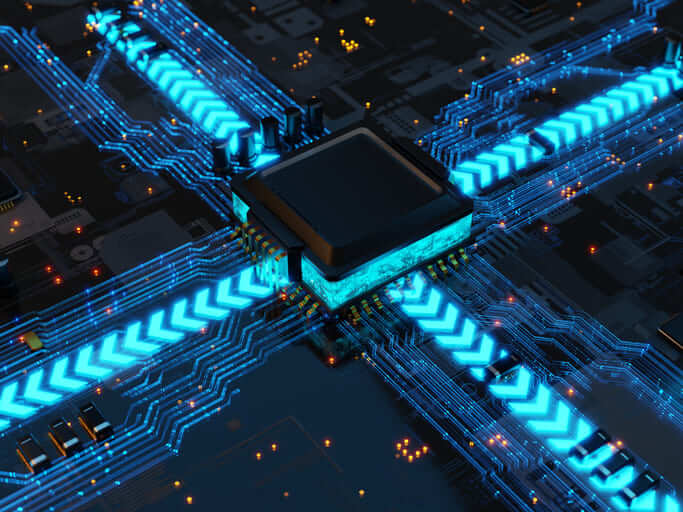

In many cases, this simplified model is sufficient—but not when it comes to high-frequency signals. And what exactly qualifies as high frequency? It’s not limited to radio frequency (RF) circuits. Any modern telecommunications equipment relies on fast signals whose spectrum ranges from baseband up to several gigahertz. A designer working with Ethernet, USB, or PCI Express must apply the same principles as an RF engineer: energy doesn’t travel as voltage and current confined within conductors, but rather as electric and magnetic fields that surround the traces and interact with other signals. In other words, you have to consider Maxwell, not just Kirchhoff.

If we want circuit traces to travel as a balanced differential pair—with a specific characteristic impedance, a defined spacing from other pairs, matched delay, and so on—this cannot be represented in a standard electronic schematic. So how can we ensure during the design process that the final printed circuit board (PCB) actually meets these requirements?

Constraints

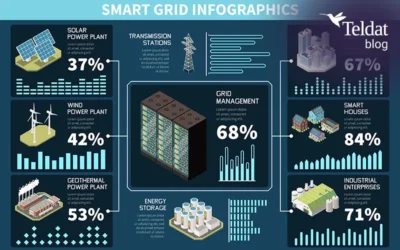

Modern electronic design software allows engineers to incorporate additional information between the schematic and the PCB layout using constraints. These constraints enable designers to define rules—such as requiring that Ethernet traces connect first to a transient voltage suppressor (TVS) before reaching the communications chip. This connection order, or topology, helps ensure that disturbances like surge waves, electrostatic discharges, or fast electrical transients are attenuated before reaching the transceiver. It also ensures signals travel along properly terminated paths, free of stubs and reflections.

Other types of constraints define, for example, the required spacing between signals to avoid cross talk, the distance between conductors belonging to different voltage domains that must maintain galvanic isolation for electrical safety, or the minimum trace width for carrying high currents, among many others. In addition, the physical capabilities of the PCB manufacturer must be specified in the design software, including the number of layers, layer spacing and dielectric constant, minimum trace width, drill sizes, spacing tolerances, and so on.

You might ask: is it really worth spending hours learning a new section of the software and entering all that data? In theory, you could route everything manually without defining any rules beforehand. But when dealing with a large number of signals, each with specific requirements, relying solely on attention and memory inevitably leads to human error. That’s why it becomes essential to complete the constraint tables with all the necessary requirements for signal integrity, EMC, safety, and manufacturability.

Design Rule Check

In the final stage of the design, the software verifies that every component, trace, via, and plane complies with the rules defined at the beginning of the project. This thorough process is known as the Design Rule Check, or DRC.

We can draw a parallel with the organization of a state. In an absolute monarchy, the king could make any decision without limitations or oversight. Today, however, we understand that a well-functioning system begins with a constitution and laws that define what is and isn’t allowed. Then comes the executive branch, which allocates resources to pursue specific goals, and finally the judiciary, which ensures that everything is carried out in accordance with established rules. Likewise, in electronic engineering, there is no room for improvisation. The “constitution” would be the set of standards required for European conformity, symbolized by the CE mark. The constraints function like laws, and the designer—who places components and routes traces—acts as the executive branch. In the end, the DRC serves as the judicial authority, verifying that everything meets the predefined rules.

One might assume that if component placement and routing are constrained by design rules, the software would automatically prevent violations, making a final DRC unnecessary. However, the Design Rule Check verifies compliance with the current set of constraints—which may have changed during the course of the project, leaving traces that were valid under earlier rules but are now outdated. It also checks for other essential conditions: ensuring no components are missing, that all connections or nets are fully routed, and that there are no loops or unnecessary trace segments.

Teldat’s electronics are developed using advanced design tools that ensure both functionality and compliance through the use of design constraints.