In complex mine scenarios, where machinery roars, dust rises and darkness reigns, communications become essential tool to shine light on safety and efficiency. Not only that, but they support coordination, decision-making and the well-being of workers.

In complex mine scenarios, where machinery roars, dust rises and darkness reigns, communications become essential tool to shine light on safety and efficiency. Not only that, but they support coordination, decision-making and the well-being of workers.

For instance, inside a mine, communications are used to connect construction vehicles and set up an information exchange network. When communications are unstable and fail, they bring operations to a complete halt (which, in turn, severely impact the return on investment).

Communication challenges inside a mine

Providing reliable and efficient communications inside a mine poses a series of challenges due to the hostile and complex nature of any underground environment.

Signal propagation: Radio waves, especially those of higher frequency, are significantly attenuated and reflected by rock walls, resulting in “shadow” areas where the signal is weak or non-existent.

Interference: Heavy machinery and electrical systems generate electromagnetic noise that can interfere with radio signals, distorting communication and causing errors in data transmission.

Changing topology: Mines are constantly expanding and changing. New tunnels and chambers are dug, while existing ones suffer modifications. As a result, the communications infrastructure needs to be flexible and adapt in order to provide coverage across all areas.

Security: Communications inside a mine need to be secure and reliable to ensure any sensitive information is being protected, workers are safe, and all operations run smoothly.

How to provide communications inside a mine

The first step is to identify which items need to be connected. In this blog post, we will specifically look at construction vehicles, fixed machinery, and monitoring devices and sensors.

Construction vehicles: Construction vehicles (such as trucks, excavators and loaders) need to be connected to the communication network for location tracking, performance monitoring, and route optimization purposes.

Stationary machines: Stationary machines (such as crushers, conveyors, and conveyor belts) need to be connected in order to be controlled remotely, as well as for condition monitoring, fault detection and process optimization purposes.

Sensors and monitoring devices: Sensors and monitoring devices installed throughout the mine must communicate with the control room to collect data on temperature, ventilation, air quality, presence of hazardous gases and other environmental parameters.

These are infrastructure-related systems, and they transmit data that are crucial for operation (such as operating status, operating parameters, environmental conditions, vibration and noise, wear and tear and consumption, GPS positioning, error codes and log data).

This information allows operators to monitor the mine, optimize operations, plan maintenance work, respond to emergencies and improve overall efficiency and/or productivity.

By understanding which elements require communications and what type of data they need to transmit, an efficient communications solution can be developed.

Indoor Wi-Fi network

A Wi-Fi network is a type of wireless network designed to provide wide and uniform signal coverage in large spaces or complex layouts. It works thanks to multiple devices (called nodes or access points) connected together to create a single Wi-Fi network.

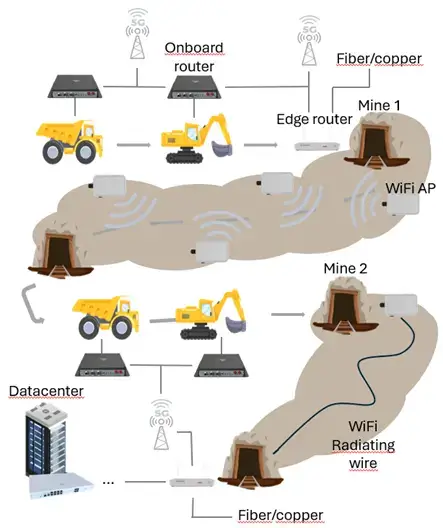

This solution aims to implement a network of robust Access Points that will be deployed inside the mine (with fiber optic access or cellular back-up at the entrance). These Access Points will work together with radiating cables for Wi-Fi cables in locations where the mine structure prevents the signal radiated by access point antennas from propagating.

In addition, in locations where power supply to the equipment is difficult, batteries will be used to ensure the availability of the network during service operation.

Communications inside construction vehicles

Once the Wi-Fi mesh has been implemented, the next step is to enable communications between the vehicles themselves. In addition, vehicles must be able to communicate when in transit from mine to mine. For this purpose, construction vehicles must be equipped with cellular communications. For this, a router must be installed in the vehicles. This router must meet all the applicable requirements in terms of environment, vibrations, temperature, humidity, dust resistance, robust structure, and connectors (as well as the ability to transmit data via Wi-Fi and the 5G/4G cellular network).

The following image shows a possible network architecture:

Source: Javier Sanchez de la Poza

As shown here, the equipment inside construction vehicles will have two ways of sending data simultaneously: 5G when the link is available, and the Wi-Fi network while inside a mine. The mine’s Wi-Fi network will be connected to the Edge router that has both 5G/4G communications and fiber or copper wire-based communications.

As seen in this blog post, the mining environment is a niche that brings great challenges for communication companies. However, by using a robust solution we can implement an architecture that meets the scenario’s strict environmental requirements.

Teldat has almost 40 years of experience in communication solutions, meaning mining companies can implement this entire network using a single provider.